Livsforlængende medicin til smittede med hiv-virus, så de ikke får aids i udbrud – såkaldte ARVs – ruller snart ud fra fabrik i Tanzania. Behovet er enormt.

DAR ES SALAAM, 6 March 2012 (PlusNews): Commercial production of Tanzania’s first locally manufactured antiretroviral drugs (livsforlængende medicin) will start in the next few months; it is hoped the country will eventually provide medicines for half of all HIV-positive Tanzanians.

A pharmaceutical plant has been built near the northern city of Arusha using a grant from the European Union of about 6,6 million US dollar.

In addition, Tanzania Pharmaceuticals Industry – in which the government has a 40 percent stake – has contributed 963.000 dollar to the project, while German medical aid Action Medeor added 660.000 dollar.

Tanzania has a national HIV prevalence of about 5 percent, but HIV levels are as high as 15 percent in southern areas of Iringa and Mbeya.

According to the government’s 2010 country progress report for the UN General Assembly Special Session on HIV/AIDS, just 21,5 percent of HIV-positive Tanzanians had access to treatment.

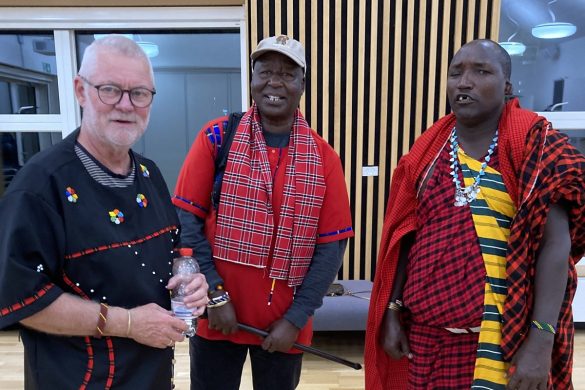

“Anti-retroviral treatment is one of the pillars for successfully fighting the HIV pandemic. This factory will help to continuously supply the disadvantaged in Tanzania and is an important step towards improving access to therapy,” said Bernd Pastors, executive director of Action Medeor.

Before the new factory was built, Tanzanian producers formulated active pharmaceutical ingredients (APIs) into ARVs; this means they imported the ingredients – mainly from China – and then formulated the combination and packaged the tablets. Now the whole process can be done on-site.

“This project is a departure for us, looking instead at building the capacity within Tanzania to produce its own HIV/AIDS pharmaceutical products at highly competitive prices, using cutting-edge technologies,” said the EU’s head of delegation to Tanzania, Ambassador Tim Clarke.

Clarke said much of this technology had been imported from similar production units in India.

The factory produced its first batches of drugs for opportunistic infections at the beginning of March; its first ARV, Efavirenz – a first-line ARV – will be produced for registration within one month following a slight delay in starting production after equipment at the plant, including copper wires and blower fans, was stolen.

Læs videre på

Begynd fra “Co-operation with a generic licence-holder on…”